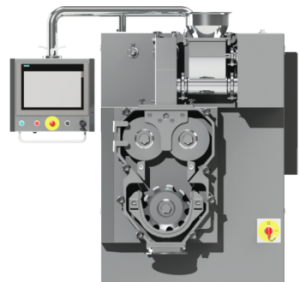

The CP 600 is our second largest pharmaceutical roller compactor with a throughput of up to 250kg/h.

In order to guarantee a high quality of the finished product (dry granulate), the quality of the pressed strip is also decisive. A constant pressure of the rollers as well as a variable roller gap which is controlled precisely by a hydraulic system guarantees the constant density of the pressed strip.

Characteristics and Benefits

- High performance press roller feeding with two metering screws

- Easy dissembling parts for quick cleaning

- Space-saving thanks to compact design

- Vacuum deaeration without additional parts

- Professional operating system and data processing

- Batch oriented operation

- Large 12 inch touch screen

- Complete IQ / OQ documentation

- Operating system is based on Windows 10

All FAYTEC pharma roller compactors feed the rollers with two efficient metering screw which are arranged horizontally and vertically. In order to avoid powder jamming when feeding the product, the metering screw of our roller compactor always have the same size and can therefore run at the same rotation speed. This feeding concept coupled with a sophisticated air deaeration guarantees a constant powder feed to the press rolls without air inclusions.

Continuous production Continuous production up to 250 kg/h.

- Vertical and horizontal metering screw For a constant good powder filling of the press rolls, horizontal and vertical metering screws. A rotating lump breaker in the feed hopper guarantees best filling of the metering screws.

- Vacuum deareation When processing products with very light density, the vacuum deaeration can help to in feed easier the product in to the compaction area.

- Press roller cooling The roller compactor CP 600 can optionally be equipped with press roll cooling for temperature-sensitive products.

- Large dimesions of the press rollers Generously dimensioned press rollers of 200 mm help to feed even the most difficult products to the rollers.

The transparent security door for monitoring the hole production process.

- Remote service The system can be connected via the network connection J45 to the machine supplier.

- HMI software Excellent data processing with optional PAT system (Process Analysis Tool). Furthermore, the controller is available with the option Data processing according to CFR 21 / part 11 (Audit Trail).

Options

- Roller surfaces adapted to application and product

- Wash in place WIP

- Connection to peripheral systems

- Integrated rollers cooling circuit

- PAT-system (Process Analysis Tool)

- Data processing to CFR 21/pt11

- Remote service

Applications

Roller compactor for pharmaceutical and food industries

- Tablets

- Encapsulate

- Instant powder

- Antibiotics

For more information Contact Us