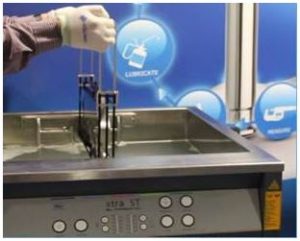

I Holland brings to you the fastest and most efficient method for cleaning segments, punches and dies, saving you valuable space. The ultrasonic method provides repeatable cleaning results compared to manual cleaning so you can remove stubborn contaminants from all of your tooling in a lot less time!

I Holland’s specially designed segment fixtures fit perfectly into the ultrasonic tank and leave the bores unobstructed, meaning effective cleaning of the entire segment. The pivot design allows for an easy drying and drainage process, and the basket coating prevents scratching and damage… You don’t have to worry about anything.

On top of all of this, Find the below additional Features for your check:

- Fixture designed specifically for tablet press segments

- Pivot design

- Coated holding fixture

- Safe/easy handling of the segments during cleaning process

- Multi-frequency at 25/45 Hz + sweep & pulse functions

Benefits of the cleaning step are:

- Allows for accurate assessment of tooling condition during inspection.

- Prevents on going damage to tooling from corrosive product.

- Reduces compression tooling problems.

- Ensures the removal of residue to avoid product contamination.

- Can help prevent sticking.

What are the benefits of ultrasonic segment cleaning?

- Unobstructed bores allow repeatable cleaning

- Allows for easy drying & drainage process

- Both faces of segment cleaned equally

- Prevents scratching.

- Allows user to easily handle the segment after cleaning.

- Repeatable cleaning results vs. manual cleaning process.

- Easily removes stubborn contaminants

Please let us know if your requirement, we will be glad to assist you.

For more information Contact Us