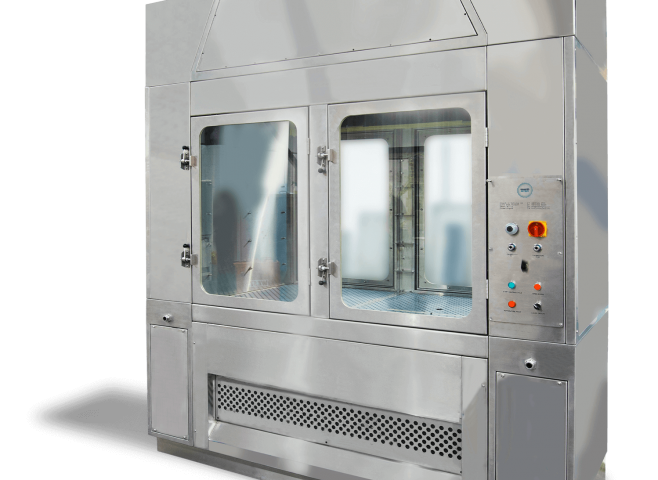

Process Isolators are containment systems that allow the handling of toxic substances for various industries including pharmaceuticals.

Our high containment isolators provide advanced performance levels for both API and HPAPI, backed by a service that’s ultra-focused on your needs.

We work closely with you to gain an all round understanding of your requirements, evaluating ergonomic-related issues to improve isolator efficacy and improve operator protection.

They can provide primary and secondary containment around pharmaceutical and chemical process activities.

Howorth has developed a wide range of innovative containment solutions for protecting personnel and the environment from potent pharmaceutical compounds. These solutions are carefully designed to ensure that they work in harmony with the core processes they are providing a barrier against. Dispensing and Sub-division For example, Howorth has developed an extensive number of isolator systems for use in the dispensing and sub-division of APIs and other compounds. Capable of nanogram levels of protection these systems incorporate features such as…

1. Single or multiple chambers

2. Fully interlocked air-locks, doors & visors

3. HEPA filtration on inlet & oulet vents

4. A number of transfer system options

5. Isolator raise/lower systems for operator comfort

6. Fully integrated & flush-mounted weigh scales

7. Automated or manual drum tippers

For more information Contact Us