Induction homogenizer Type HVIS

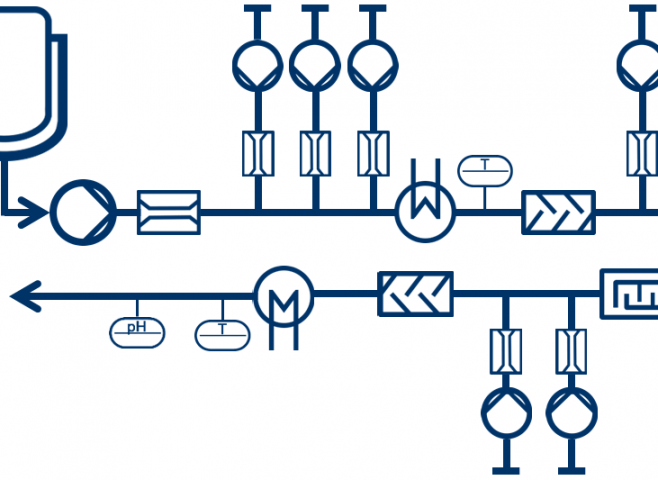

The symex induction homogenizer is a new development to complement the extensive range of equipment for mixing and homogenizing liquids and powders. The new homogenizer generates a vacuum so that no separate vacuum pump is required. This is the optimal solution for a fast and controlled way to work powders into liquids. The induction homogenizer can be used either in combination with main mixing vessels or with prephase vessels.

These downstream plants can be specifically designed for the entire process and can be vacuum and pressure resistant as well as atmospheric. The advantages of the system are particularly evident during the incorporation of very light and volatile or heavy and sticky powders. In the mixing section a direct wetting of the powder occurs, so the powder will not float or sink when it enters the vessel. Powders can be worked into aqueous or oil-containing phases.

All advantages at a glimpse

- Simple upgrade for mixing plants which are equipped with a homogenizer or bottom agitator and a return line Induction of very light or heavy powder

- There is no danger the powder will enter the process unmixed or unwetted, as is the case when it is added to a vessel under vacuum

- Regulated and metered addition into the media flow through a controlled valve at the inlet of the powder

- Mixing and feeding of small quantities is possible

- Several variants of symex homogenizing tools can be installed

- Highest flexibility through selection of flow rate and shear rate

- Automatic adjustment into the vacuum-generating mode, automatic triggering of the intake and permanent

pressure monitoring in the induction housing - Effective integration of the system into the CIP process

- Delivery on base frame with control cabinet

For more information Contact Us