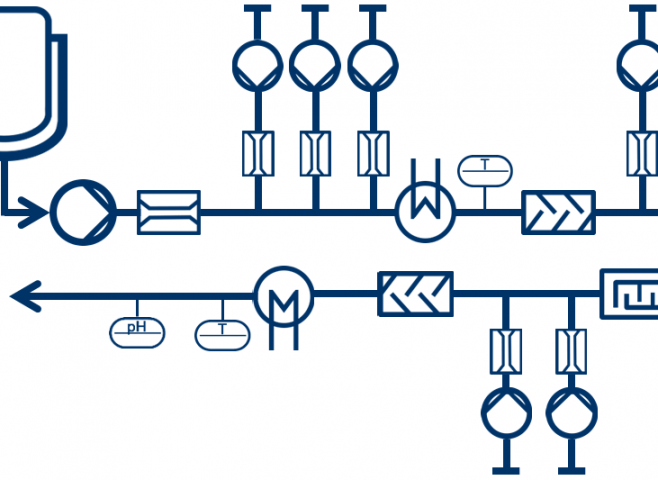

Application of InLine homogenizer and equipment features:

HE type (rotor-stator principle) or optional HC type symex Inline Co-Twister (rotor-rotor principle)

- Standard homogenizer (rotor-stator principle)

- Installation sizes: 100, 250, 250/500, 500, 1000, 2500/1000, 2500

- Connection variants: DIN 11851 pipe, DIN 32676 or ISO 2852 clamp, DIN 2633 flange, special flange

- Stand alone mixing unit on a mobile transport Frame or fixed machine support

- Mixing chamber with multi-rim rotor-stator mixing tools

- Motor, air- or water-cooled, with variable-speed drive

- Double-acting mechanical seal cooled and lubricated by controlled sealing liquid system (standard or aseptic)

- SIEMENS controls with touch panel, control cabinet (in stainless steel) Option to connect to existing control systems

- Stainless steel machine support lined with sound-insulating material protects the homogenizer and constantly keeps the sound pressure level down.

Options:

- Version as Co-Twister homogenizer (rotor-rotor principle). Independent setting of flow rate and shearing/energy input via differential speed in shearing gap

- Venturi induction for the induction of liquid and powder materials even without vacuum directly into the intake stream of the homogenizer

- Connection of a powder induction lance

- Attachment of a powder hopper

- Sensors in mixing chamber

- Flow meter

- Diaphragm valve for throttling the volume flow

- Induction housing for special induction function (for operation on vacuum vessel)

For more information Contact Us