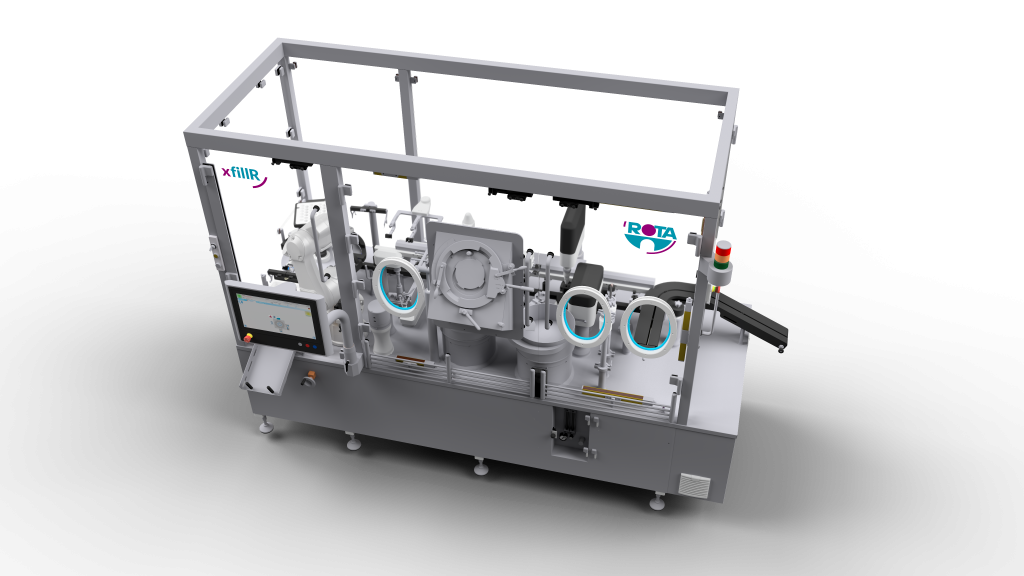

Filling and Closing Machine for Small Batches

ROTA xfillR aseptic filling system is the perfect fit for processing the smallest batches in research and development as well as in the production of batches for clinical trials in the pharmaceutical and biotech industry. Filling different containers with just one extremely compact machine means not only time and cost savings, but also an investment in flexibility and thus lasting independence.

xfillR is also the ideal system for processing small batches in the biotech industry.

Advantages

Processing of a wide variety of objects

The xfillR is the innovative development of a multipurpose machine for processing different objects such as vials, syringes, eye droppers, nasal sprays, cartridges, micro-tubes or Sarstedt® tubes, in nests, trays and in bulk.

To close the objects, the xfillR can handle various types of closures, such as stoppers, droppers, aluminum caps, screw caps, spray pumps, RayDyLyo®, etc.

To close these objects, xfillR also handles a wide variety of closures, such as stoppers, plungers, droppers, aluminum caps, screw caps, snap-on closures, RayDyLyo® etc.

Gentle transport

The xfillR and its precise individual handling of each object guarantees gentle transport without glass/glass or glass/metal contact. Scratches and particle emissions are thus avoided.

Everything with one compact machine

With the xfillR it is possible to process all cylindrical objects, whether RTU (Ready To Use) in nests or trays, whether free standing or not, in complete batches or just a single object. Filling is accomplished by means of a rotary piston pump or a peristaltic pump. The 100% check of the filling is done with a weighing cell. Finally, plugs, piston plugs or droppers can be inserted and caps placed, crimped, screwed or snapped on.

Properties

+ Unique and multipurpose machine

+ High flexibility – “all in one” solution

+ Small batch sizes from 1 to 10,000

+ Modular design, expandable at any time

+ Processing of a wide variety of objects

+ Versatile closures can be processed

+ High versatility of closures

+ Very compact design, also available as a wall installation

+ Short changeover time

+ Easy to operate

+ High degree of automation due to full servo-drive system

+ Suitable for RABS & Isolator – from aseptic to high potent application

Popular options

+ Debagging station for nested objects

+ Debagging station with inverting device for vials in trays.

+ 100% or statistical weigh-check verification & control

+ “Zero-Reject“ – system

+ Peristaltic pump filling

+ Recirculation system for suspensions

+ RTP alpha port

+ cRABS or Isolator

+ Particle monitoring

+ Qualification documents

+ Electronic batch protocol

+ 21CFR Part 11 compliance

+ Batch record printer

+ Filling by peristaltic pump

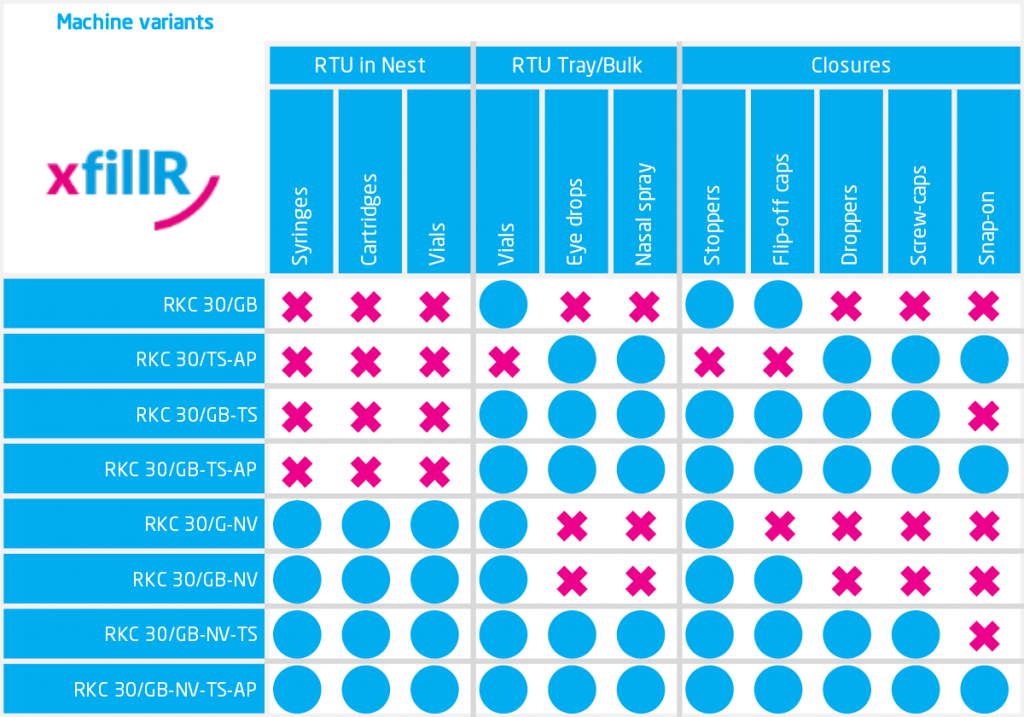

Model Versions

For more information Contact Us