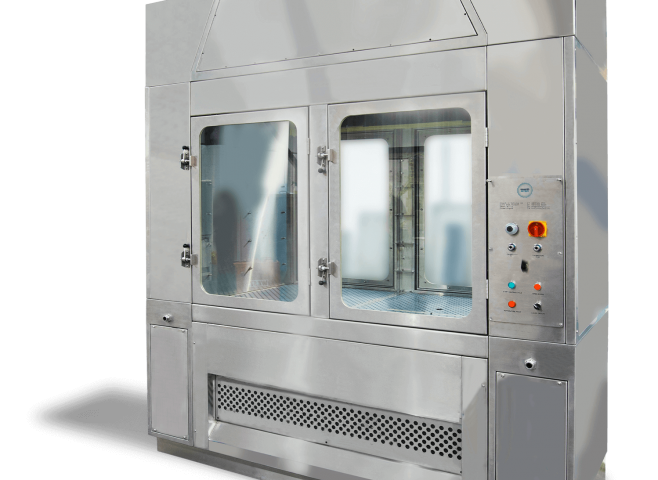

Aseptic isolators are routinely found within the pharmaceutical industry and are widely used for sterile injectable drug filling and sterile & pharmacy drug compounding. They are designed to provide continuous and complete isolation of the inside of the isolator from the external room environment (including its operators). This ensures that the environment is maintained as contamination-free to safeguard patients who will later be administered the drug.

Widely used for a number of applications including:

Sterility testing

Compounding

Sterile injectables

Pharmacy dispensing

Liquid filling

Aseptic transfer

Medical device manufacture and assembly

Packaging

Integration of key monitoring, processing and decontamination systems

For more than 150 years, the Howorth name has representedtechnical creativity and expertise in air engineering and its application to protect people and products from contamination.

Threat of contamination Human operators pose the greatest risk to product contamination during “conventional cleanroom” aseptic processing and manufacturing. Even under optimal conditions, a gowned, motionless human may generate 100,000 particles per ft3/min within a cleanroom, while a walking operator may generate 10,000,000 per ft3/min Using isolation systems minimizes the extent of personnel involvement and separates the external cleanroom environment from the aseptic processing line.

A positive pressure isolator or Restricted Access Barrier system (RABs), supported by adequate procedures for its maintenance, monitoring, and control, offers tangible advantages over classical aseptic cleanrooms, including fewer opportunities for microbial contamination during processing.

For more information Contact Us