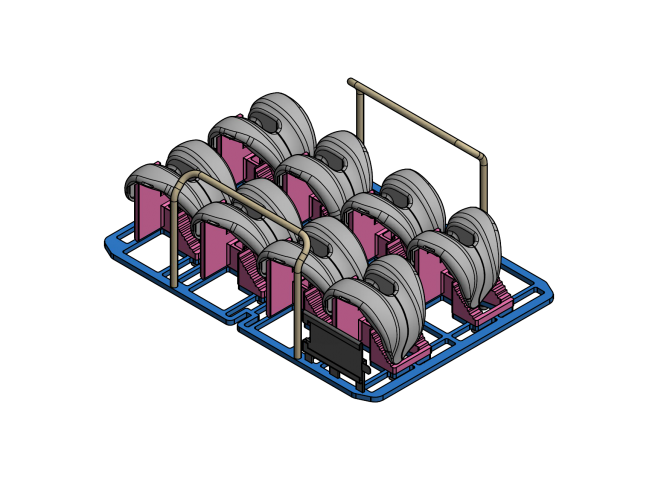

T-BCC: Automated Washing & Drying System for IBCs, Drums, Pallets

Various Cleaning Applications

Usable Chamber

Dimension1500x1500x2000 mm

IBC‘s 550L – 2,100L

• Drums 60L – 200L

• Aluminum Pallets

• Plastic Buckets

• Machine parts and accessories

Two Chamber Washing and Drying

• Automatic sliding doors

• Inflatable door seals

• Completely welded chambers

• Cycle time: Approx. 15 to 20 minutes with cooling to 50°C.

• Water consumption approx 600–800 L/cycle

• Washing lance for interior cleaning of IBC / Drums

• Rotating wash head for cleaning outlet flap of IBC

• Washing system for exterior of IBC, Drums, etc.

Specifications

• All wetted parts 316L SS

• cGMP Design

• FDA compliant components

• Load / Unload height 500 mm

• 3 digital detergent dosing systems

• Conductivity control for final rinse

• Hygienic circulation pump, heat exchanger, circulation piping

• HEPA filtered drying air

• Siemens S7-315 PLC controls

• HMI panel MP 377

• WinCC flexible architecture

• CFR21 part 11 compliant

• Optional Scada doc system

For more information Contact Us