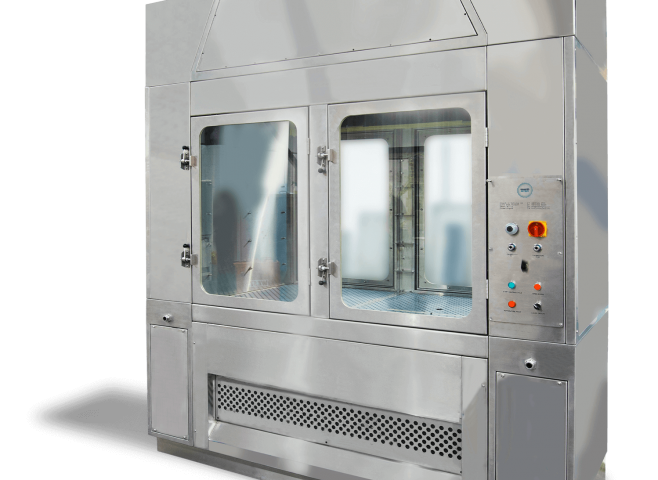

Our BIOGEN Decontamination Systems can be effectively integrated into an ENVIROSAFE™ isolator, bringing more precision to protection in small volume enclosures such as safety cabinets, microbial incubators and glove box isolators. It efficiently disperses and extracts Hydrogen Peroxide vapor within the chamber, ensuring a better-protected environment.

Our BIOGEN decontamination technology can be fully integrated into an ENVIROSAFE™ isolator.

This cost-effective decontamination solution brings greater precision to protection in small volume enclosures such as safety cabinets, microbial incubators and glove box isolators.

BIOGEN Decontamination System manually draws up a developed amount of 33 to 35% Hydrogen Peroxide and disperses the vapor via an ultrasonic nozzle to fill the chamber. The cycle is completed once the vapour is extracted.

Next Generation – The Howorth BioGen Duo NGVHP Generator

Unlike earlier generation models, where H2O2 is vapourised by introducing it to a hotplate, the Next Generation BioGen design achieves this by ultrasonication, negating the requirement for system conditioning and with much faster dosing rates. Liquid H2O2 is transferred at 100ml/min to the ultrasonic generator, where it is converted to VHP at <3µ.

There is no need to dehumidify the room or chamber as this system can operate at up to 95% RH. Unlike the second generation example, there is also no need for complicated valving to change from gassing to aeration loops, with a simple switchover so that the catalyst draws VHP/air from the decontamination area to break down H2O2 into water and oxygen.

For more information Contact Us