ENGINEERING

Engineering there is an area dedicated to Facility Planning. This activity consists of the analysis, study and design the lay-out, as a preliminary step, often strategic, of a process aimed at creating and / or restructuring of industrial sites (both individual departments of entire production sites).

The proposed approach starts from a definition of the strategic concepts of a Site Master Plan that optimizes manufacturing processes, in relation to the flows (materials, people and vehicles), and comes to define the system solutions, technological and procedural optimal, consistent with the places constraints. The Site Master Plan does not invest only the technical side, but considering the economic parameters, research and development, acquisitions and transfers of production, marketing, presenting to the management or ownership proposals from which you immediately perceive the effectiveness of ‘ economic and technical operation. Furthermore, it constitutes a specific peculiarity of this study and the design of handling and storage systems and installations (Material Handling) in support of the above processes.

CSV Life Science offers services Conceptual Engineering, Basic Engineering and Detail. The validation background allows CSV Life Science to follow all phases of the project taking into account the cGMP issues.

- Conceptual Engineering.

- Basic Engineering.

- Detailed Engineering and Supervision.

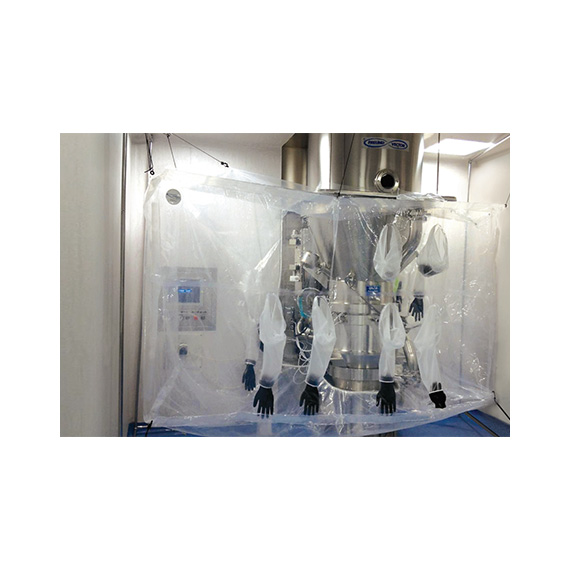

The expertise gained in the pharmaceutical sector and the technical background of chemical engineers that make up the rich section of CSV Process, allows to deal with both the design in the secondary field of production and, therefore, relative to the finished and packaged products, both the design of installations and / or production sites of active ingredients (API), where the process (chemical or biotechnological synthesis) and the engineering of the same require specific technical skills and at the same time a GXP sensitivity.

CONCEPTUAL ENGINEERING

CSV Life Science is able to follow the development of a project from the early stages. The main

activities during the Conceptual Engineering are:

- Definition of designated areas for the production plant and the support areas lay-out definition and possibly Process Flow Diagrams.

- Classification areas trails personnel / materials.

- Definition Main process equipment and utilities of the plant investment estimation (± 25 ÷ 30%).

BASIC ENGINEERING

The next step CSV Life Science is able to offer are services related to Engineering Base. In this phase all that has been set previously is consolidated, and can then initiate other actions aimed at the realization of the plant, such as for example:

- Lay-out equipment Process.

- Lay-Out generation equipment and storage utilities.

- Design Criteria HVAC.

- P & ID HVAC.

- P & ID Process Fluids and service.

- P & ID Process.

- Lay-Out pipes.

- Lay-out Channels.

- Pre-sizing major utilities generation equipment.

- Specifications Equipment Process.

- List Equipment.

- List Tools.

- List Fluids.

- Definition consumption.

- Activities program.

- Investment Estimation system (± 10 to 15%).

The amount and type of documentation defines in this step the degree of accuracy of the estimate and therefore the development of basic engineering.

DETAILED ENGINEERING AND SUPERVISION

CSV Life Science is able to develop all the engineering activities of detail, which in addition to consolidating what has been proposed in phase of basic engineering, complement each other in terms of drawings and documents the remaining part of the plant object of activities.

CSV Life Science so good, customers in the choice of different suppliers or contractors who will work in the construction of the plant, through an activity of collecting the various offers made homogeneous, and subsequent technical and economic tabulation of the same.

The CSV Life Science activities continues with a follow up of the various contractors, checking the consistency of the proposals in relation to the shared project. During the realization phase CSV Life Science is able to provide support to the customer in overseeing the progress of the project even with an active presence (Construction Management), and starting up the same (Commissioning).

The development of a number of commissioning procedures, which are approved by the client company, used to define how to check and to manage the data collection (using calibrated instrumentation), responds to the need to make the fastest possible qualification phase of the plant; the data collected in the process of commissioning are a decisive support for the subsequent qualification activities.